Selecting Leather-Different Weighs, Styles, Cuts, Hides, Skins-How Leather is Sold-Leather Tanning Processing

SELECTING LEATHER

|  |

| The hides of large animals such as Cow are generally sold in the cuts indicated above. Sides are the most common cut of Vegetable Tanned Cowhide… and Double Shoulders are the most popular cut for the making of belts. | The hides of smaller animals such as Sheep, Deer or Goat are generally referred to as Skins and sold as whole hides. |

HOW LEATHER IS SOLD

Generally, leather is sold by the square foot or by the pound. When sold by the pound, the leather is weighed when shipped from our warehouse… per pound pricing usually applies to Skirting, Harness or Sole Leather. When leather is sold by the square foot, the hides are measured at the tannery and are usually sold in whole pieces. The actual square footage of each piece of leather will vary… no two pieces are exactly the same. The various cuts of cowhide are all sold by the square foot. Skins are priced by the square foot… but occasionally some skins may be priced by the piece (such as shearlings). Our large Saddle Skirting Sides are sold by the piece.

TANNING PROCESSES

All leathers, except rawhide, go through a tanning process. The main tanning processes available are Chrome Tanned, Vegetable Tanned and Alum Tanned. Chrome tanned leather is tanned using soluble chromium salts, primarily chromium sulfate. Vegetable tanned leather is tanned using vegetable materials derived from tree bark and various other plants. Alum tanned leather is tanned with a colorless aluminum salt and is primarily used as lace leather. Other variations are Chrome Oil Tanned, where chrome tanned leather is treated with oil to help preserve the leather… and Retanned where vegetable tanned leather is simply retanned using chrome salts or chrome leather is retanned using a vegetable process.

LEATHER

- The proper thickness of leather is important to any project. The Leather Substance Table below provides comparative figures to clarify terms used in the leather industry to indicate leather thickness.

- The thickness of most craft leather is designated by “ounce”, which is 1/64″ in thickness. Sole leather which may be used by sandal and shoe makers is measured in terms of “iron” which is 1/48″ in thickness.

- Even though most leather is subjected to some splitting and leveling to minimize variations, each cut will have some variation of thickness and the weight is therefore indicated as a range… such as 7-8 ounce or 12-13 iron.

- Leather is measured and marked at the tannery, with square footage usually indicated in sq. ft. and quarter ft….for example: A hide with a measurement of 23-2 would mean 23 1/2 sq.ft. Pigskins are usually measured in sq. ft. and tenths…. for example: 23.2 would mean 23 and 2 tenths sq.ft. An electronic device is used by the tannery to accurately compute the square footage in each piece of leather.

- Leather used in the shoe industry and upholstery industry is commonly measured using letter symbols to indicate thickness. Example: LL(2 -2 1/2 ounce), L (2 1/2 – 3 ounce), LM (3 -3 1/2 ounce), M (3 1/2″ – 4 ounce), HM ( 4- 4 1/2 ounce), H (4 1/2 – 5 ounce). HH (5 – 5 1/2 ounce), HHH (5 1/2 – 6 ounce).

| LEATHER SUBSTANCE TABLE | ||||

| Inch | Millimeter | Decimal | Ounce | Iron |

| 1/64″ | .40 | .0165 | 1 | 3/4 |

| 1/32″ | .80 | .0313 | 2 | 1 1/2 |

| 3/64″ | 1.20 | .0469 | 3 | 2 1/4 |

| 1/16″ | 1.60 | .0625 | 4 | 3 |

| 5/64″ | 2.00 | .0781 | 5 | 3 3/4 |

| 3/32″ | 2.40 | .0938 | 6 | 4 1/2 |

| 7/64″ | 2.80 | .1094 | 7 | 5 1/4 |

| 1/8″ | 3.20 | .1250 | 8 | 6 |

| 9/64″ | 3.60 | .1406 | 9 | 6 3/4 |

| 5/32″ | 4.00 | .1563 | 10 | 7 1/2 |

| 11/64″ | 4.40 | .1719 | 11 | 8 1/4 |

| 3/16″ | 4.80 | .1875 | 12 | 9 |

| 13/64″ | 5.20 | .2031 | 13 | 9 3/4 |

| 7/32″ | 5.60 | .2188 | 14 | 10 1/2 |

| 15/64″ | 6.00 | .2344 | 15 | 11 1/4 |

| 1/4″ | 6.40 | .2500 | 16 | 12 |

| 17/64″ | 6.80 | .2656 | 17 | 12 3/4 |

| 9/32″ | 7.20 | .2813 | 18 | 13 1/2 |

Leather Terms Glossary

Aniline: Leather that is treated all the way through with transparent dye. The effect is applied by immersing the leather in a “dye” bath. Because the finish is transparent and shows the natural markings, only the best quality hides can be used.

Antiqued: Leather that is dyed with one color over another (usually darker over lighter) so as to create rich highlights and an artificialyl aged appearance. Also referred to as “distressed” leather.

Brain Tanned Leather: This leather is made by a labor-intensive process which uses emulsified oils extracted from animal brains, typically deer or elk. They are known for their exceptional softness and their ability to be washed.

Bridle: #1 US Cowhide, vegetable tanned with waxes and aniline oils added for outdoor wear. Has a smooth, waxy feel, with very smooth flesh side. Can be oiled or embossed. Drum Dyed after finish tanning, so may have a slightly lighter center than outside finish. Used for canine, equine tack and for high-end belts. Available in 5 colors : Black, Havana Brown, Chestnut, Saddle Tan and Medium Brown

Buffed Leather: Leather from which the top surface has been buffed by abrasion. Suede is an example of splits that have been buffed. Nubuc is an example of top grain leather that has received buffing.

Corrected Grain: Leather that has been buffed to remove blemishes, then covered with new artificial grain created by using pigments and other finishes.

Crust: Leather that has been tanned (treated to become nonperishable), but not colored or otherwise finished.

Distressed: Another term for antique leather.

Dosset: A dosset is a leather shape, many times referred to as a “double back.” It is basically a whole hide with the neck and belly portions trimmed off. Dossets are a popular choice for natural “oak tanned” leather for use in belts and straps. Dossets are normally large in size, up to 40 square feet, and will average approximately 76+” in length.

Drum Dyed: The process of coloring leather by tumbling it in a rotating drum immersed in dye. A very effective method allowing maximum dye penetration.

Embossed Leather: Leather that has been stamped or pressed with a design under a very high pressure. This can be a design pattern or grain texture such as alligator hide.

Finish: An enhancing effect applied to leather after it has been tanned. Examples are dyeing, embossing, buffing, antiquing, waxing, waterproofing and so on. A finish can also refer to the top coating that is applied to a leather surface to protect, enhance or seal the leather.

Full Grain Leather: Leather that has not been altered except for hair removal. Full grain leather is the most genuine type of leather, as it retains all the original texture and markings of the original hide.

Glazed Leather: Aniline-dyed leather which has been polished to a high luster by passing through glass or steel rollers under great pressure.

Glove Leather: Very soft leather that is typically used for gloves. This can be lamb, deer or soft tanned cowhide.

Grain: A word used to describe the natural characteristics of a leather hide, such as its pores, wrinkles, markings and texture.

Hand: A word used to describe the feel (i.e.: softness of fullness) of leather.

Harness: #1 US Cowhides, vegetable tanned and hot stuffed with oils and waxes for outdoor wear. The flesh side has a smooth, waxy finish. Hot Stuffed, then drum dyed, so Black will not be struck all the way through, and will have a semi-natural center. Used for heavy equine and tack items. Offered in Natural, Russet Tan and Black

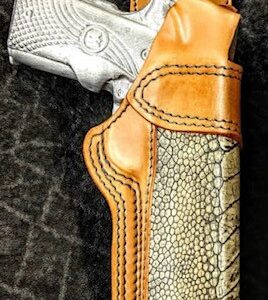

Horse “Butt” Leather: This erroneous term is often used to describe the strips that are cut from horse leather in the production of shell cordovan. These strips are actually in front of the butt section of the horse hide. Prized for their low cost and durability, this leather is used for items such as baseballs, gun holsters and knife sheaths.

Latigo: #1 US Cowhide, vegetable tanned, then re-tanned with chrome and oils and for outdoor extreme wear. Leather is drum dyed, then oils and waxes added, so the color it all the way through the hide. Used for both canine and equine tack items, and many other uses. Offered in Burgundy and Black

Nap: Describes the soft, “fuzzy” effect achieved in leather by buffing or brushing.

Natural Grain: A leather that displays its original grain.

Nubuc: A top grain leather that has been buffed or brushed to create a soft, velvety effect. Differs from suede in that while suede is created from the flesh (inner or split) side of the leather, nubuc is created using the grain (outer) side, thus giving it added strength and durability.

Oil Tanned: Leather that is tanned or re-tanned using a variety of oils to create a soft finish and to make the leather more resistant to weather conditions. Oil tanned leathers are used mainly in the tack and shoe industries.

Patina: The aura or luster that develops in a quality piece of leather with age.

Perforated: Leather in which a pattern of small holes is stamped. Used mainly in automotive upholstery.

Plating: The process of pressing leather under a heated plate. Often used in upholstery leather to mask imperfections.

Pull-Up: Describes the behavior of leather that has been treated with oils, waxes and dyes in such a way that when leather is pulled or stretched, the finish becomes lighter and the underlying base color is more evident. Popular for upholstery, shoe and boot leathers as well as for luggage and handbags.

Rawhide: Rawhide is made by scraping the skin thin, soaking in a lime solution, then stretching it while it dries. Rawhide is stiffer and more brittle than other forms of leather. Its main uses are in production of drum heads and for saddle tack. Rawhide will stretch up to 25% when soaked in cold water then shrink back when dyed. Most rawhide is sold in the natural state “honey color” but can also be bleached to give a whiter appearance.

Re-Tan: A second finish process that is added over an underlying tannage.

Sauvage: A coloring effect created by blending two similar dyes to create a mottled or marbled appearance.

Semi-Aniline: Aniline leather to which a matching pigment layer is added to even out the color and add protection.

Shell Cordovan: A very dense, hard and durable leather produced from a small area on horse butt leather. It is oval in shape, tanned, stuffed, shaven and polished in a process that takes about 6 months to produce a piece of leather that is only about 1 – 1.5 square feet in size. Prized for its harness and durability.

Side Leather: Leather made from one-half or “side” of a full hide. Typically refers to top grain leather. Most saddle tack leathers are sold as a side leather such as bridle, harness, latigo, skirting and strap sides.

Split Leather: Leather made from the lower (inner flesh) layers of a hide that have been split away from the upper (grain) layers. Not as strong or durable as full grain leather. Typically this leather is milled and turned into suede leather.

Suede: Leather that has been buffed and brushed to create a “fuzzy” feel. Typically this leather is produced from splits that are dyed, then milled to create a soft hand.

Top Grain: Leather that the outer most layers have been left intact. Leather is considered top grain as long as the grain side in intact but some correction can be applied.

Two-Tone: An effect created by applying layers or contrasting dyes to a piece of leather in order to create a mottled or aged appearance.

Upholstery Leather: Leather crafted from a whole hide and intended for use of furniture, auto or aviation industries. Full hides are used to increase the cutting area for large cut patterns.

Vegetable Tanning: A method of hide tanning which utilizes organic materials such as bark instead of traditional chemicals. Sometimes called “Oak Leather” because oak bark is sometimes used in this process. Some tanneries will use chestnut or other types of bark in their tanning process. This method of tanning is considered to be more environmentally friendly than traditional chrome tanning methods. Vegetable tanning is the preferred method for leather that is used for carving and embossing. Most bridle, latigo, harness and natural strap leather are vegetable tanned.

Weight: A term used to describe the thickness of leather. Typically in ounces, irons or millimeters.

Wet Blue: Another term for Chrome Tanned Leather. This process was invented in 1858 using chromium sulfate and other salts of chromium. It is more supple and pliable that vegetable tanned leather and does not discolor or lose shape as drastically in water as vegetable tanned. Wet Blue leathers are the base leather for most oil tanned and bag leathers that are widely used in the shoe, luggage and accessory industries. One the leather hides have been processed into the Wet Blue state they can be shipped, stored and processed into others types of leather hides. Wet Blue or Chrome “Pearl” sides are also used in their wet blue state for gloves, work aprons and many other uses.

Whole Hides: Refers to leather created from a whole hide as opposed to cut pieces. Typically upholstery leather or hair on hides.

Recent Comments