Exotic Leather Color Options

Hello,

Below is a list of our Exotic Leather color options, keep in mind that the colors may change in shade slightly due to every animal hide has pores and may absorb more color than others. Also, some photos are taken with more of a lighter/brighter shade due to the lighting. If you would like to learn more about the benefits of each exotic leather, please click the link below to our FAQ page to learn more. Check out other BLOG articles concerning our exotic leather. If you are looking for another color or another exotic leather than please send us an email to sales@mtrcustomleather.com and provide us a picture of the shade of color and we will try our best to meet your needs. Keep in mind, some exotic leather or color options may not be in stock due to the exotic leather shortage.

Royal Blue, Pink, Natural (bottom middle)

Royal Blue, Pink, Natural (bottom middle)

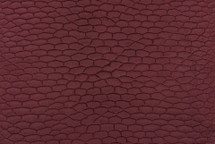

Brown Hippo Leather

Brown Hippo Leather Lizard

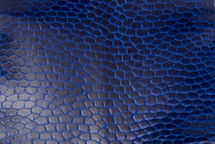

Lizard Stingray Color Options

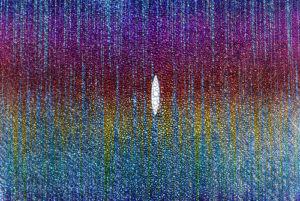

Stingray Color Options Rainbow Stingray

Rainbow Stingray

Cognac Shark

Recent Comments